A Practical Guide to Battery Thermal Management in Modern Energy Storage

Definition

A liquid cooling system in BESS is an active thermal management solution that uses circulating coolant to remove heat from battery cells, keeping temperatures stable, improving safety, and extending battery lifespan.

Why It Matters

Liquid cooling enables higher energy density, better temperature uniformity, and safer operation, making it the preferred cooling method for modern high-power and containerized BESS.

As battery energy storage systems (BESS) grow larger and more powerful, thermal management has become one of the most critical design considerations. High-capacity batteries generate significant heat during charging, discharging, and fast response operations. If this heat is not managed properly, it can reduce performance, shorten battery life, and increase safety risks.

This is why liquid cooling is rapidly becoming the standard cooling solution for modern BESS installations—especially for containerized systems, high-voltage battery racks, and utility-scale projects. Unlike traditional air cooling, liquid cooling offers precise temperature control, higher efficiency, and better support for dense battery configurations.

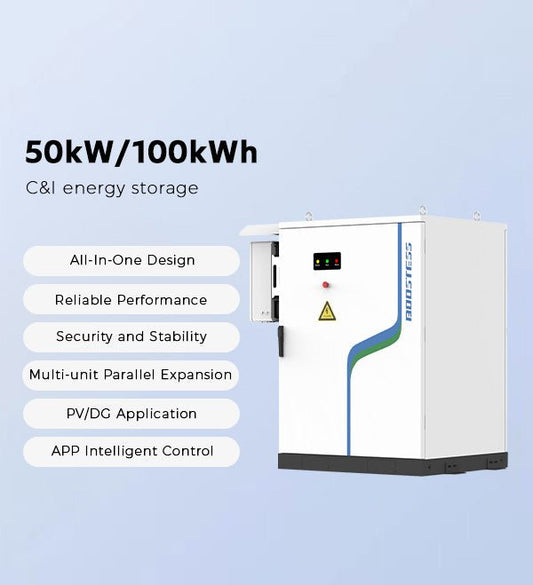

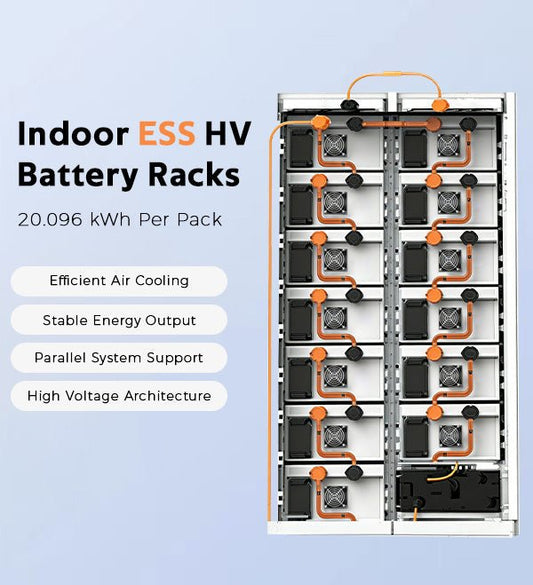

In this guide, we explain what a liquid cooling system in BESS is, how it works, how it compares to air cooling, and when it is the right choice. Whether you are evaluating a liquid-cooled BESS, an Indoor ESS High Voltage Energy Storage system, or a large renewable project, this article will help you understand why liquid cooling matters.

Why Thermal Management Matters in BESS

Heat Generation in Battery Energy Storage

Battery cells naturally produce heat due to:

- Internal resistance during charge and discharge

- High current flow in high-power systems

- Fast response requirements for grid services

In large BESS installations, thousands of cells operate simultaneously, making heat accumulation unavoidable.

Risks of Poor Thermal Control

Without effective thermal management, BESS may face:

- Accelerated battery degradation

- Reduced usable capacity

- Increased risk of thermal runaway

- Higher maintenance and replacement costs

Thermal control is not optional—it is fundamental to safe and reliable energy storage.

What Is a Liquid Cooling System?

Definition of Liquid Cooling in BESS

A liquid cooling system uses a circulating coolant—typically a water-glycol mixture or specialized dielectric fluid—to absorb heat directly from battery cells or modules and transfer it away from the battery.

Unlike air cooling, liquid cooling actively regulates battery temperature across the entire system, maintaining an optimal operating range regardless of load or ambient conditions.

Liquid Cooling vs Passive Cooling

Liquid cooling is an active system:

- Controlled circulation

- Sensors and automated response

- Precise temperature regulation

Passive or air-based cooling relies heavily on ambient air and is less effective at high power densities.

How Liquid Cooling Works in BESS

Core Components of a Liquid Cooling System

A typical liquid-cooled BESS includes:

- Cooling plates or coolant channels near battery cells

- Pumps to circulate coolant

- Heat exchangers or chillers

- Temperature and flow sensors

- Control unit integrated with EMS or BMS

Cooling Process Step-by-Step

- Heat is generated by battery cells

- Coolant absorbs heat through plates or channels

- Heated coolant flows to a heat exchanger

- Heat is released to the environment

- Cooled liquid recirculates

Liquid Cooling vs Air Cooling in BESS

Key Technical Differences

|

Feature |

Liquid Cooling |

Air Cooling |

|

Cooling efficiency |

Very high |

Moderate |

|

Temperature uniformity |

Excellent |

Uneven |

|

Energy density support |

High |

Limited |

|

Climate tolerance |

Strong |

Weak in extremes |

|

System complexity |

Higher |

Lower |

Performance in Real Projects

Liquid cooling performs significantly better in:

- High-power BESS

- High ambient temperatures

- Compact containerized systems

Air cooling is often sufficient only for small or low-power ESS.

Benefits of Liquid Cooling for Battery Energy Storage

Supports Higher Energy Density

Liquid cooling allows batteries to be packed closer together, enabling:

- More kWh per container

- Smaller system footprint

- Higher power output

Extends Battery Lifespan

By maintaining stable temperatures, liquid cooling:

- Reduces thermal stress

- Slows cell degradation

- Increases cycle life

Enhances Safety

Efficient heat removal lowers:

- Hot spot formation

- Risk of thermal runaway

- Fire propagation

Liquid Cooling in Containerized BESS

Why Containerized Systems Prefer Liquid Cooling

Containerized BESS environments are:

- Enclosed

- Space-limited

- High in energy density

Liquid cooling solves airflow limitations and ensures uniform cooling throughout the container.

Typical Applications

- Utility-scale BESS

- Solar and wind power plants

- Grid stabilization projects

Liquid Cooling for Indoor ESS Systems

Advantages for Indoor Installations

In Indoor ESS High Voltage Energy Storage systems, liquid cooling offers:

- Low noise operation

- Reduced HVAC dependency

- Compact rack layouts

Integration with Safety Systems

Liquid cooling integrates with:

- Fire detection

- Gas sensors

- Emergency shutdown systems

This makes indoor ESS safer and easier to manage.

Explore our 125kW/261kWh BESS C&I Energy Solutions solutions for liquid-cooled applications.

Liquid Cooling in High-Voltage Battery Systems

HV Battery Thermal Requirements

High-voltage batteries operate with:

- High current density

- Fast charging and discharging

- Concentrated heat zones

Liquid cooling ensures these systems operate within safe limits.

Supporting High-Power Operation

Liquid cooling enables:

- High C-rate discharge

- Fast response grid services

- Stable long-term performance

Learn more about our 241 kWh battery solutions designed for liquid-cooled ESS.

Safety and Reliability Considerations

Leak Prevention and Monitoring

Modern liquid cooling systems use:

- Sealed closed-loop designs

- Pressure and flow sensors

- Automatic alarms

Redundancy and Fail-Safe Design

Critical systems include:

- Redundant pumps

- Emergency shutdown logic

- Fault isolation mechanisms

Energy Efficiency and Operating Costs

Energy Consumption of Liquid Cooling

While pumps consume energy, liquid cooling:

- Reduces battery losses

- Improves overall system efficiency

Lifecycle Cost Benefits

Over the system lifetime, liquid cooling:

- Extends battery life

- Reduces replacement frequency

- Lowers total cost of ownership

Typical Use Cases for Liquid-Cooled BESS

- Utility-scale energy storage

- Commercial & industrial ESS

- Renewable energy integration

- Extreme climate installations

Liquid cooling is especially valuable where performance and reliability are critical.

Common Myths About Liquid Cooling

“Liquid Cooling Is Too Complex”

Modern systems are modular, factory-tested, and highly reliable.

“Air Cooling Is Always Enough”

Air cooling struggles with:

- High density

- High ambient temperatures

- Large-scale systems

Liquid cooling solves these limitations.

How to Choose Between Liquid and Air Cooling

Key Decision Factors

- System size and power

- Battery energy density

- Ambient temperature

- Indoor vs containerized installation

When Liquid Cooling Is the Better Choice

Liquid cooling is recommended for:

- Large BESS projects

- High-voltage battery systems

- Long-duration, high-value installations

Why Liquid Cooling Is the Future of BESS

As battery energy storage systems continue to scale, liquid cooling is becoming the preferred solution for managing heat, ensuring safety, and maximizing performance. By enabling higher energy density, longer battery life, and reliable operation in demanding conditions, liquid cooling transforms how modern BESS is designed and deployed.

For projects using HV battery packs, containerized BESS, or Indoor ESS High Voltage Energy Storage systems, liquid cooling is no longer optional—it is a strategic advantage.

0 comments